Raw material prepared in

specific proportions depending on the desired grade, then metals are

melted, other materials added to enhance machinability. Once melted, the

components are thoroughly mixed to create a uniform alloy.

- info@kevalind.com

-

+91 93130 55001

Process

Keval Industries

Our Manufacturing Process

-

1. Melting and Alloying

-

2. CastingThe molten is poured into molds or billets, depending on whether the next step invloves extrusion, Forging or rolling. The casting process can vary according to size of components.

-

3. FormingOnce it solified the piece undergoes forming process like extrusion, forging and rolling.

-

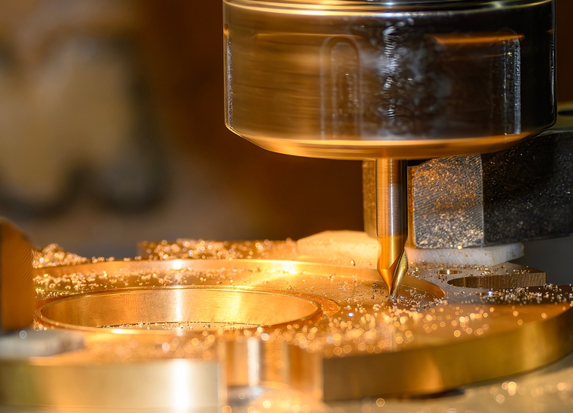

4. MachiningThe processes are used to create fine details or features in components are, turning, milling, drilling, and threading. Computer Numerical Control (CNC) machines are employed for highly accurate and complex parts, and removal of sharp edges and burrs formed during machining.

-

5. Hot TreatmentThe components undergo annealing to soften the material and relieve internal stresses from the forming or machining process, quenching and tempering may also be used to hardness and durability.

-

6. Surface FinishingThe products are being polished for resulting in a smooth, shiny surface, and can be coated with the metals as per requirement of product for enhanced corrosion resistance or decorative purpose and then a transperant protective layers may be applied to prevent tarnishing.

-

7. Quality Control and InspectionThe finished components undergo through Inspection to ensure it meets specifications and standards for dimensions, surface finish, and mechanical properties.

-

8. Packaging and DistributionAfter quality control, components are packaged to prevent damage during transportation and are they ready to be dispatched to the buyers and customers.